Common Sewage Treatment Device Introduction

Marine sewage treatment plant can be roughly divided into three types according to the working principle, such as biochemical method, physical and chemical method, electrolysis method, etc., in which the most common ship is the use of biochemical method (the use of biochemistry of the traditional activated sludge method) to deal with sewage sewage treatment plant. The principle of biochemical method is based on the device in the fan supply into the conditions of sufficient oxygen, the use of domestic sewage into activated sludge with sewage contact, and with the activated sludge biochemistry will be removed to reduce the value of organic matter BOD5 (Escherichia coli), and at the same time, with the help of the adsorption of activated sludge and coagulation will be adsorption of solids in suspension deposits, and then oxidized under the action of the bacterial species into inorganic substances, the rest into Protoplasm that can constitute bacterial cells allows bacteria to grow and multiply, and then discharged after disinfection.

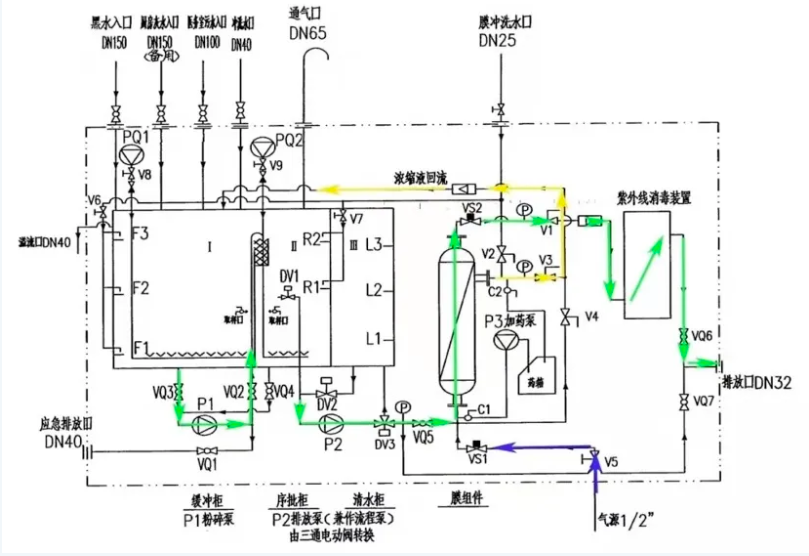

Domestic sewage first into the pretreatment cabinet impurities are filtered into the aeration tank, air supplied by the aeration fan into the sewage, by making the air to produce strong stirring, so that the domestic sewage and activated sludge is fully mixed, and at the same time to ensure that aerobic microorganisms need oxygen. After aeration, the organic matter in the sewage will be dissolved by the activated sludge and transformed into CO2, H2O and other inorganic substances. Thereafter, the activated sludge enters the sedimentation tank with the sewage and settles at the bottom. In the sedimentation tank, the treated water after sedimentation flows into the sterilization tank from the overflow pipe to sterilize the water, and then is automatically discharged out of the gangway by the discharge pump controlled by the high and low level float switch.

Inspection Points

1. Certificate record check

(1) Confirm that all kinds of certificates, such as the International Certificate for the Prevention of Pollution from Domestic Sewage or the Certificate for the Prevention of Pollution from Domestic Sewage from Ships at Sea, the Type Approval Certificate for Domestic Sewage Treatment Device, and the Table of Domestic Sewage Discharge Rates (if any), are complete and valid.

(2) Confirm that the records of domestic sewage disposal meet the requirements of discharge, focusing on the comparison between the record book of domestic sewage discharge of the ship and the logbook, ship voyage plan, electronic charts, etc., to determine whether there is any problem of illegal discharge of the ship, as well as whether the ship's voyage speed and the rate of discharge when discharging satisfy the requirements, and for the ship equipped with the collector cabinet, focus on the verification of the ship whether it is discharged according to the requirements of the approved "Domestic Sewage Discharge Rate Table". Table".

(3) By checking the certificate of domestic sewage and the type approval certificate, check whether the treatment capacity of the ship's domestic sewage treatment device meets the needs of the ship. In accordance with the requirements of "Domestic Navigation Technical Rules for Statutory Inspection of Seagoing Vessels 2020", the daily amount of domestic sewage generated by the ship can be calculated as follows: When no other clear supporting documents can be provided, the following calculation method can be referred to: (1) When the voyage time from the port of departure of the ship to the discharge location specified by the port authorities is more than 24h, each person per day and night is calculated in accordance with the 70L; when the voyage time is between 8h to When the sailing time is between 8h and 24h, each person is calculated according to 35L; when the sailing time is between 4h and 8h, each person is calculated according to 18L; when the sailing time is between 1h and 4h, each person is calculated according to 9L; when the sailing time is less than 1h, each person is calculated according to 6L; if the commode installed on the ship is of the vacuum flushing type, then the calculation values corresponding to the different sailing time periods mentioned above can be reduced by half.

2. Inspection of domestic sewage treatment device

(1) Appearance inspection

Check whether the model and rated capacity of the domestic sewage treatment device on board are the same as those listed in the certificate; check whether there is any corrosion and leakage, whether the nameplate, warning plate, pipeline and valve labeling are clear and accurate, and whether there is a pipeline diagram of the domestic sewage treatment and an operation guide or operation instructions hanging beside the device.

(2) pipeline flow inspection

Focus on checking whether the port domestic sewage outboard valve is closed and locked, whether the valve is in good condition, whether it is closed in place; inspection of the pipeline to determine the role of each valve, focusing on checking whether the domestic sewage pipeline into the device, whether there is bypassing the valve in violation of the discharge and so on.

(3) Equipment use condition inspection

Mainly check the operating parameters of the domestic sewage treatment device (including pump discharge pressure, air pump pressure, circulating water membrane), pump working conditions, liquid level alarm, disinfection equipment and other working conditions:

① check the control panel power supply, indicator, buzzer, control switch is normal, pay attention to the discharge pump control switch is normal in the "automatic" mode (docked in Hong Kong need to be adjusted to "manual" mode).

② check whether the crushing pump, discharge pump is normal working conditions.

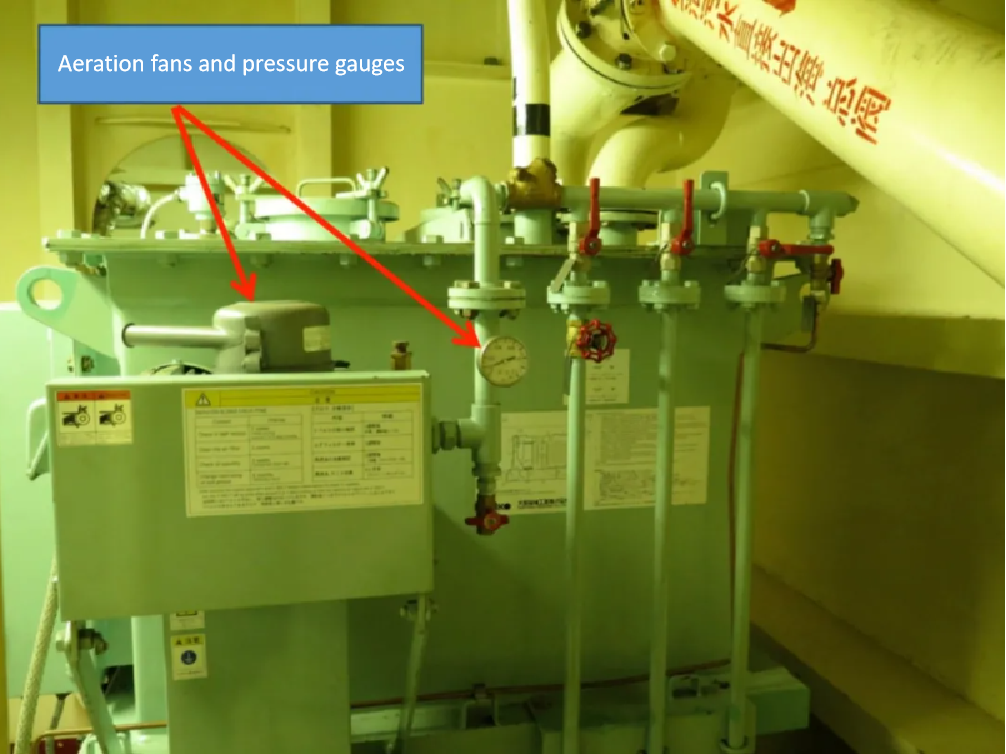

③ Check whether the fan is in automatic working condition, whether the fan condition is normal, whether the fan pressure is normal, whether it is in the range required by the manual (generally 0.02 ~ 0.03MPa). For some devices will ship compressed air as a fan as an alternative measure, pay attention to determine whether the pressure value can reach the range required by the manual.

The role of the fan is to produce airflow through the aeration of domestic sewage for oxygen supply, and at the same time as the sewage cycle back to the driving force.

④Check whether the return flow of the return pipe is normal or not. Ship's domestic sewage treatment device usually has two return pipes between the aeration chamber and the sedimentation chamber, and the activated sludge at the bottom of the sedimentation chamber and the solid materials such as scum at the top will return to the aeration chamber through the return pipe under the action of airflow.

⑤ Check whether the valve switch of each chamber of the device is correct. There are several valves on the connecting pipelines between the chambers inside the treatment device and the discharge pipeline. Only the outlet valves of the disinfection chamber and the discharge pump should be in the open state when the device is in normal operation, and all other valves should be closed. When the aeration chamber, precipitation chamber, contact chamber export pipeline valves are not in a closed state, untreated sewage will be through such valves directly into the discharge pipeline and lead to illegal discharge of domestic sewage into the sea. Therefore, when checking, attention should be paid to verifying whether several valves in Fig. 7 are switched on and off correctly.

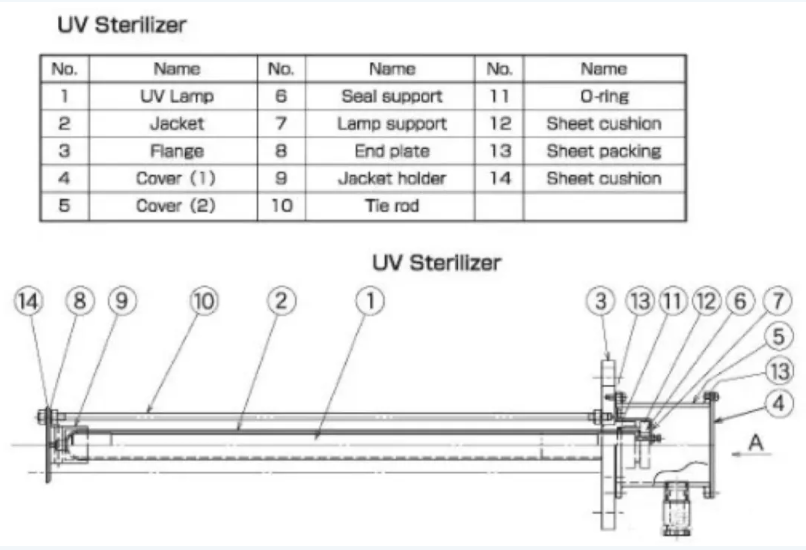

⑥Check whether the disinfection device is working properly.

There are three common forms of disinfection for the domestic sewage treatment device on board, namely, disinfection by dosing port, ultraviolet ray disinfection and liquid disinfectant disinfection by quantitative pump pumping. From the point of view of the disinfection effect, the quantitative pump pumped into the liquid disinfectant disinfection method disinfection effect is better, in the ship is more and more widely used. At present, many domestic sewage treatment devices use a combination of two disinfection methods in the form of ultraviolet disinfection + dosing port dosing disinfection.

For the dosing port should check whether the dosing records in accordance with the requirements of dosing, whether the drug is in the validity period, whether there is no caking and failure, dosing port is open, etc.; for the quantitative pump pumped into the liquid disinfection should check whether the dosing pump and its pipeline is good for ultraviolet disinfection should be checked whether the ultraviolet lamps are all working properly, whether the lamps are damaged and so on.

⑦Check whether the liquid level high alarm of domestic sewage treatment device is normal.

Domestic sewage treatment device on the level electrode generally have three levels, from bottom to top: low level - discharge pump start level - high level alarm level, for the float switch control device, can be shorted to the wire for high level alarm test, or the discharge pump control mode adjusted to manual, through the way of water filling Test the high liquid level alarm.

(4) Inspection of dirt collecting cabinet

Since the "Ship Water Pollutant Discharge Control Standard" (GB3552-2018) has come into effect, which stipulates that the discharge of domestic sewage from ships should be carried out during the ship's voyage, in order to avoid the domestic sewage not being able to be processed because of the ship's long anchoring time, most of the ships have been retrofitted with a dirt collecting compartment/cabinet. For the inspection of sewage collection tanks, the inspector should first determine how the tanks are used on board, and distinguish whether the black water enters the tanks directly or enters the tanks after being treated by the domestic sewage treatment device. If the black water enters the tank directly, the tank should meet the requirements of MRRPOL Annex IV and be equipped with an approved Domestic Sewage Discharge Rate Table, which should be indicated on the ISPP certificate, and the tank should be equipped with a level indicator. If the black water is treated by the domestic sewage treatment device and then entered into the collector to be stored and discharged, the industry prefers not to manage it as black water, and then the collector will not be required too much. As this arrangement of piping is more complex, so during the inspection, the inspector must carefully verify the piping and the switching status of each valve to avoid accidental discharge of the ship due to valve switching errors, and focus on checking whether there is a sneak discharge piping.

(5) Standard discharge connector inspection

Check whether the standard discharge joints are corroded, whether the bolts are complete and whether the flanges are of standard size.

(6) Crew operability check

Verify the crew's familiarity with the operation of the domestic sewage treatment device. The crew should not only be familiar with the basic principles of the domestic sewage treatment device and the operating procedures of the domestic sewage treatment device of the ship, but also be familiar with the requirements for the discharge of domestic sewage, and understand the spares and spare parts required for daily maintenance.

(7) Sampling and inspection

When the inspector holds suspicion on the operating condition of the device, it can take on-site sampling and professional laboratory methods for testing if necessary.