Daily Inspection of Ship Sewage Treatment Device

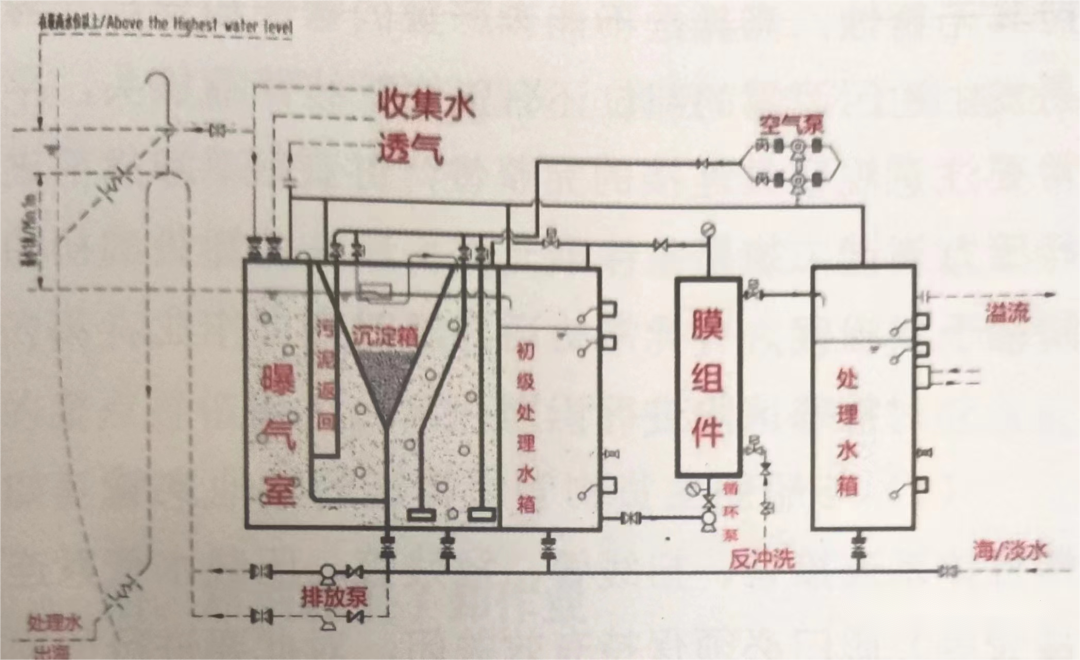

Its working principle is: ① domestic sewage into the aeration tank, through aerobic bacteria and microorganisms (propagated by the domestic sewage after exposure to oxygen) for decomposition; ② domestic sewage from the aeration tank into the sedimentation tank, and in it the flocs of aerobic bacteria (generally known as activated sludge) precipitated; ③ clarified liquids into the primary treatment tank, through the ceramic membrane separation system to get qualified water and into the treatment water tank Until discharged outboard. At the same time, the circulation pump will pump the secondary biochemical treatment water in the primary treatment tank to the membrane module for automatic backwashing. Detailed description is as follows:

Daily inspection of Ship sewage treatment device

1.Weekly

Check the pressure gauge reading of the air compressor (should be 0.015~0.054MPa), the membrane module outlet pressure gauge reading (should be 0.1MPa), the membrane module backwash air supply pressure gauge reading (should be 0.4MPa), and the sludge return in the sludge return pipe.

2. Monthly

Switch to the spare air compressor and make sure its outlet valve is open before switching, then close the outlet valve of the compressor that has stopped working; check the amount of activated sludge in the biochemical reactor by using the randomly supplied measuring cylinder and fill 100 ml of water samples in the cylinder and let it stand for 30 minutes; if the height of settled sludge has exceeded 60 ml, the sludge must be partially discharged.

3. Every six months

Check whether the filter drum of the compressor is clogged or not, whether the check valve on the air supply line is intact or not, and replace or clean the filter drum.

4. Every year

Empty and clean all the tanks and check the wear and tear of the discharge pump and compressor. If the air pressure of the pressure gauge rises to 0.054MPa, clean or replace the air diffusion element.